- mdi can help!

- The mdi Sales Team is standing by to help you with your order or questions about our Products. Give mdi a Call Today!

- 727-835-0648

- Email our Sales Team

- Office Hours: 7:00 am - 7:00 PM EST M - F

Cyclone Separator

LAYOUT

The cyclone separator is ideally suited as a bulk water separator when located before a refrigerant dryer or directly after the compressor if no air receiver is used; or if it is placed at a distance; or if the compressed air supply pipe is mounted vertically.

EFFICIENCY

Apart from the drain, the cyclone separator operates wear free because there are no moving parts which means increased output of the compressed air treatment system.

MINIMAL PRESSURE LOSS

There is a minimal pressure loss across a cyclone separator which means that operating pressure is always optimized – saving energy.

DRAINS

A time controlled condensate drain is fitted as standard. An electronically level controlled, zero-loss, BOGEmat condensate drain can be fitted as an option assuring increased compressed air treatment safety and lower enegy costs.

Operating principle

DF-C Cyclone Separators deliver high separation efficiency at low pressure drop through an optimal flow-path design. An innovative insert in the cyclone head creates centrifugal action that forces liquid and particulate to the housing wall. Friction with the housing causes the liquid and particulate to lose part of their kinetic energy and drop out of the higher moving airstream. Collected condensate is removed by a time controlled condensate drain, while the purified compressed air or gas exits to the industrial application downstream.

Maintenance free filtration:

The BOGE heavy-duty cyclone separators

take liquids, aerosols and solids from the compressed air. Based on the

law of inertia they operate with practically no maintenance – ideally

suited for compressed air systems without an air receiver when directly

installed downstream of the compressor.

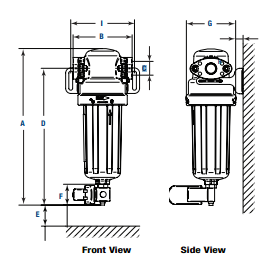

| size | Flow Rate** | Volume | Weight | Dimensions (inches) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| scfm | gal | lbs. | A | B | C in fnpt |

D | E | F | G | H min/max |

I | |

| Z20N | 80 | 0.106 | 3.5 | 11.14 | 4.06 | ½" | 9.6 | 4.53 | 1.93 | 3.35 | 0.88 / 2 | 4.2 |

| Z35N | 140 | 0.304 | 5.9 | 14.51 | 5.5 | ½" | 12.7 | 7.1 | 1.93 | 4.6 | 0.88 / 2.8 | 5.9 |

| Z53N | 210 | 0.304 | 5.9 | 14.51 | 5.5 | 1" | 12.7 | 7.1 | 1.93 | 4.6 | 0.88 / 2.8 | 5.9 |

| Z75N | 300 | 1.32 | 6.4 | 22.5 | 7.5 | 1½" | 20 | 9.8 | 1.93 | 6.3 | 0.88 / 13.56 | 7.5 |

| Z125N | 490 | 1.32 | 6.4 | 22.5 | 7.5 | 2" | 20 | 9.8 | 1.93 | 6.3 | 0.88 / 13.56 | 7.5 |

| Z188N | 720 | 1.32 | 6.4 | 22.5 | 7.5 | 2" | 20 | 9.8 | 1.93 | 6.3 | 0.88 / 13.56 | 7.5 |

** Nominal flow at 100 psig, scfm related to 14.7 psia.

Capacity Correction Factors

| System Air Pressure (psig) | 15 | 30 | 45 | 60 | 75 | 90 | 100 |

|---|---|---|---|---|---|---|---|

| Correction Factor | 0.26 | 0.39 | 0.52 | 0.65 | 0.78 | 0.91 | 1 |

| System Air Pressure (psig) | 115 | 130 | 150 | 175 | 200 | 225 | 250 |

| Correction Factor | 1.13 | 1.27 | 1.44 | 1.6 | 1.87 | 2.09 | 2.31 |

Capacity based on 100 psig inlet pressure; 14.7 psia and 68 ˚F ambient conditions.