- mdi can help!

- The mdi Sales Team is standing by to help you with your order or questions about our Products. Give mdi a Call Today!

- 727-835-0648

- Email our Sales Team

- Office Hours: 7:00 am - 7:00 PM EST M - F

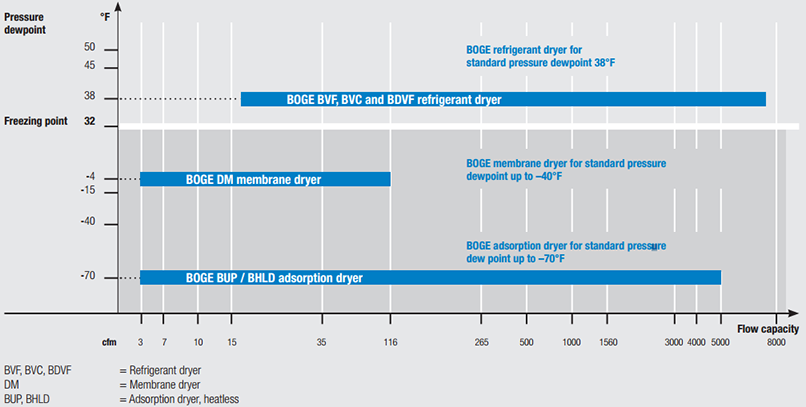

Refrigerant Dryers

Membrane Dryers

Adsorption Dryers

Particulate / Micro / Active Carbon Filters

Cyclone Separators

Condensate Drains

Condensate Treatment

Quality air pays off:

BOGE compressed air treatment

Compressed air is a versatile medium. It is widely used throughout industry and, for example, can be found in workshops and garages where untreated air is acceptable or the specialist industries where the demanding environments of the pharmaceutical and food sectors require absolutely dry, oil-free and often sterile compressed air.

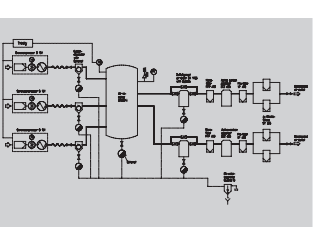

Compressed air users rely on quality air from BOGE wherever the safe and efficient treatment of the compressed air is required. Our compressed air specialists will do their utmost to configure a customized air treatment system to meet any given set of criteria.

1 cubic foot of untreated ambient air can contain up to 4 million airborne particles as well as 50 – 80% water vapor and oil in the form of unburned hydrocarbons. During the compression process the concentration of these particles increases: at a pressure of 150 psi, for example, an eleven-fold value of 44 million dirt particles is reached. Optimally treated BOGE compressed air is dry, dust-free, oil-free and if required sterile.

The Right Balance: Advantages of Boge Compressed Air Treatment

CAREFUL PLANNING AND ADVICE

When it comes to selecting the right type of air

treatment, specialist advice is crucial because

an incorrectly dimensioned system can easily

generate unnecessary costs in the long run. You

can count on the BOGE know-how: a thorough

system analysis ensures that the installed air

treatment exactly meets the site requirements.

OPTIMAL COST-BENEFIT RATIO

Compressed air treatment is a necessary cost

in a compressed air system and so the chosen

system should produce an optimal cost-benefit

ratio. An oversized or undersized air treatment

system is likely to result in unnecessary costs or

jeopardize the operating integrity of the system.

BOGE’s range of air treatment products ensures

that there is a cost effective customized solution

for every application.

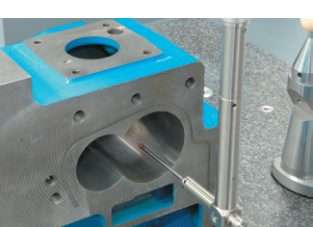

QUALITY DESIGN

The use of high quality materials and a reduced

number of wear parts ensures the BOGE air

treatment systems are as efficient and reliable

as our demanding customers rightfully expect.

The BOGE manufacturing process also meets

on-going quality standards – from inspection of

purchased parts to final inspection and testing

of each product. And, when it comes to product

development, BOGE ranks among the first for

German engineering: time after time we are

recognized as trendsetters in the industry

thanks to our innovations many of which have

Worldwide patents.

The right system for your requirements

Based on your air quality requirements

BOGE will take care of selecting the appropriate air treatment products to

provide an optimal solution from initial assessment to system design.

| Class | Solid impurities (Max. particle size per m3 ) Max. particle size in µm | Humidity (Max. pressure dewpoint) | ppm Max. oil content | |||||

|---|---|---|---|---|---|---|---|---|

| < = 0.1 | 0.1 < d < = 0.5 | 0.5 < d < = 1.0 | 1.0 < d < = 5.0 | °C | °F | mg/m3 | ppm/w/w | |

| 0 | Specified by user | |||||||

| 1 | A/R | 100 | 1 | 0 | < = -70°C | < = -94°F | < = 0.01 mg/m3 | < = 0.008 ppm/w/w |

| 2 | A/R | 100,000 | 1,000 | 10 | < = -40°C | < = -40°F | < = 0.1 mg/m3 | < = 0.08 ppm/w/w |

| 3 | A/R | A/R | 10,000 | 500 | < = -20°C | < = -4°F | < = 1 mg/m3 | < = 0.8 ppm/w/w |

| 4 | A/R | A/R | A/R | 1,000 | < = +3°C | < = +37°F | < = 5 mg/m3 | < = 4 ppm/w/w |

| 5 | A/R | A/R | A/R | 20,000 | < = +7°C | < = +45°F | - | - |

| 6 | - | - | - | - | < = +10°C | < = +50°F | - | - |

| Classes 6 and 7 are defined according to the maximum particle size and maximum density. Class 6: d < = 5 µm and density < = 5 mg/m3 Class 7: d < = 40 µm and density < = 10 mg/m3 |

Classes 7 to 9 are defined according to their liquid water content. Class 7: CW < = 5 mg/m3 Class 8: 0,5 g/m3 < CW < = 5 mg/m3 Class 9: 5 g/m3 < CW < = 10 mg/m3 |

|||||||

Boge Compressed Air Dryers